History of the company

The 21st century and the present

The company responds to market and customer demands – increasing productivity and reducing production costs. Multi-axis machines enabling complex machining of a component in one clamping and machines manufactured on the basis of specific customer requirements ROLLER 2800 and SPH 50 DS are put into production.

2021

- vertical machining centre MCV 1100 QUICK

- five-axis vertical machining centre MCV 1100 5X

2020

- change of sole shareholder to Trust Union Fund

- MCV 2220 QUICK vertical machining centre

- MCV 1400 QUICK vertical machining centre

2019

- turning centre KL 435

2018

- turning centre KL 285

2017

- introduction of hybrid WELDPRINT technology

- five-axis vertical machining centre MCU 450-5X

- MCV 800 QUICK vertical machining centre

2016

- change of sole shareholder to INDUSTRY INNOVATION a.s.

2015

- modernization of machinery equipment of production facilities

- investments in foundry and logistics

2014

- completion of extensive modernisation of the 5th floor and customer centre in the administration building

- construction of a new entrance to the administration building

- investment in machinery in the production halls

- celebration of the 75th anniversary of the company

- establishment of the MAS Automation division

2013

- construction of new modern entrance to the premises completed

- extensive investments in production (foundry and heavy halls)

- five-axis vertical machining centre MCU 1100V-5X wins Gold Medal at MSV Brno

2012

- 20.7.2012 establishment of the subsidiary MTE KOVOSVIT MAS in Azov, Russia

- continuous expansion of the product range with high-tech machines

- MULTICUT 630S/3000 multifunctional turning and milling centre

2011

- change of sole shareholder to FPK Group Limited

- extensive renovation of production facilities and administrative building begins

- five-axis vertical machining centre MCU 630 VT-5X

- establishment of a separate MAS Hydro division

2010

- KOVOSVIT MAS becomes part of BONATRANS GROUP HOLDING LIMITED

- MMC 1500 gantry machining centre

- MMC 1500 wins the Fair Award at the MSV in Nitra

2009

- CNC turning centre SP 430

- machine with special technology ROLLER 2800

- MCV 1270 Speed wins the Fair Award at the MSV in Nitra

2008

- 1. 1. 1 January 2008 establishment of the subsidiary KOVOSVIT MAS POLSKA in Poland

- MULTICUT 500 multifunctional turning and milling centre

2007

- five-axis vertical machining centre MCU 630 V-5X

2005

- five-axis machining centre MCU 630

- HiTURN 65-10X automatic turning machine

- SP 180/280 CNC turning centres

- MULTICUT 500 S (T) and SMARTURN receive the Outstanding Product of the Year award from the Design Centre of the Czech Republic

2004

- MCU 2000 gantry machining centre

- MCU 2000 SPEED wins the Innovation of the Year Award from the Association of Innovative Entrepreneurship of the Czech Republic

2002

- SMARTURN 160

2001

- SPM 16 CNC turning centre

2000

- MCV 1000 vertical machining centre

90s

The first half of the 1990s was marked by the restructuring of the company, the search for new markets and a fundamental change in the product range. CNC control systems enable fully automatic machine operation. A new range of MCV series vertical machining centres and MASTURN universal CNC lathes are introduced.

1999

- MCV 750 A vertical machining centre, SPH 50 CNC lathe

1995

- MCV 500, 750, 1000 series vertical machining centres

1993

- SPU 20 MC twin spindle turning centre

- MCV 32 vertical machining centre

1992

- MASTURN 40 universal lathe with CNC control

1990

- SARY 42 CNC and SARY 60 CNC single spindle automatic lathe

80s

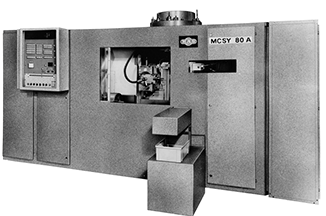

In 1983, the MCSY 50 and MCSY 80 universal turning centres were introduced. This machine became an inspiration for foreign companies and Kovosvit was ahead of its time with this machine concept. Between 1983 and 86, many machines were awarded the Gold Medal at international trade fairs such as in Brno and Leipzig.

1988

- SPU 40 CNC turning centre

1987

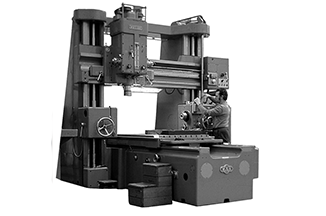

- rotary drilling machine VO 50

1986

- precision boring centre WXH 100 NC

1983

- turning machining centre with two spindles and automatic tool change MCSY 50 and MCSY 80

70s

development of electronics forces the introduction of NC-controlled machines.

1978

- production drilling machining centre VXD 100 CNC

1975

- SPT 16N wins the Gold Medal at the MSV in Brno

1973

- SPT 16 N semi-automatic turning machine

1971

- in April 1971 the construction of the new 3rd Hall was completed

- universal lathes with wide bed and NC control SP 16, SPT 32 NC

1970

- coordinate drilling machine VR 5 NC

60s

Since the 1960s, Kovosvit has been producing program-controlled machines.

1969

- On 19 March 1969 a fire occurred in the 3rd floor of the factory. In August 1969 the construction of a new hall was started.

1967

- numerically controlled drilling machine with VXR 50 NC turret head

1966

- SPT 32 wins the Gold Medal and Diploma at the Leipzig and Brno trade fairs

1963

- 29. 5. 29 May 1963 construction of the new foundry building completed

- production of the EKONOMAT SPT 20 and SPT 32 lathes begins

1962

- a new era in the design and manufacture of machine tools begins

50s

In 1952, production of horizontal drilling machines HVF 1600 and heavy planers HD 31 was started.In this year, production of single-spindle curve turning machines A 12, A 40 according to Škoda documentation was also started. In 1956, production of the WKV 100 precision coordinate boring machine was started (almost 700 units produced by 1994) .

1959

- series production of the WKV 100 coordinate boring machine begins.

1958

- SP 31 semi-automatic copying lathe wins the “World Exhibition Grand Prix” at the Brussels World Exhibition

1956

- WKV 100 precision coordinate boring machine

1955

- VRM 50 rotary assembly drill of own design

1954

- HD 31 planer (5 HD 31 planers produced between 1954 and 1957)

1953

- production of horizoners transferred from Skoda

- production of horizontal boring machines HVF 1600 introduced, further production of SPE 50 lathes and SP 31, SP 25 and SP 12 lathes

1952

- production of automatic turning machines A 12, A 20, A 40 is taken over

1951

- VRP 8 travelling radial drilling machine

40s

Production of turret and spindle lathes and radial drills is transferred from the parent plant in Zlín. From 1945 onwards, the production of radial drills of its own development of the VR 2, VR 4, VR 6, VR 8 series is followed by the production of bicycles as an additional production in the period 1941 – 1942. In 1949, the national company Kovosvit Sezimovo Ústí was founded, at that time there were already 1700 employees.

1946

- the company is renamed Bata, n p. Zlín, branch plant in Sezimovo Usti, at this time the name Kovosvit is adopted

1943

- Radial drilling machine VR 4, in the following years extended by types VR 2, VR 6, VR 8

1942

- 5th production hall built

- 742 lathes, 586 turret lathes, 144 drills produced

1940

- turret lathe R 5

- construction of foundry completed

- Construction of the third production hall and power plant completed

- construction of a five-storey office building, which was a landmark in the surrounding area, began (1,000 Jews worked on the construction)

- the number of engineers in Sezimovo Usti MAS at the end of the year is already 700

Construction of MAS machine-building plants in Sezimovo Ústí 1939 - 1949 to the present

The production of machine tools in Bata’s shoe factory in Zlín began in 1936 and in a relatively short time a comprehensive range of basic products was created. In 1938, this production in Zlín ran into difficulties in obtaining labour. The management of the company was considering transferring the focus of its activities in this field to another region – Slovakia. At this time, the company was given a new logo – the MAS brand, which at that time stood for Moravian and Slovak Engineering Works. However, events in the second half of the year put the plan on hold. After the division and occupation of Czechoslovakia, the management instructed to find another location in the territory of the Protectorate.

The events after 15 March 1939 changed the meaning of the MAS brand, which from then on stood for Moravian Joint Stock Engineering. The director of MAS, Mr. Bohuslav Ševčík, finally chose the area in the cadastre of Velký dvůr near Sezimovo Ústí. On 5 June 1939, the company purchased this site for the construction of a new plant.

1939

- 5 June 1939 purchase of land for construction

- 9 June 1939 construction work started

- November 1939 railway siding put into operation

- 20 December 1939 production of machine tools started

- turret lathe RS 25, RS 40 and spindle lathe SN 18, SN 20