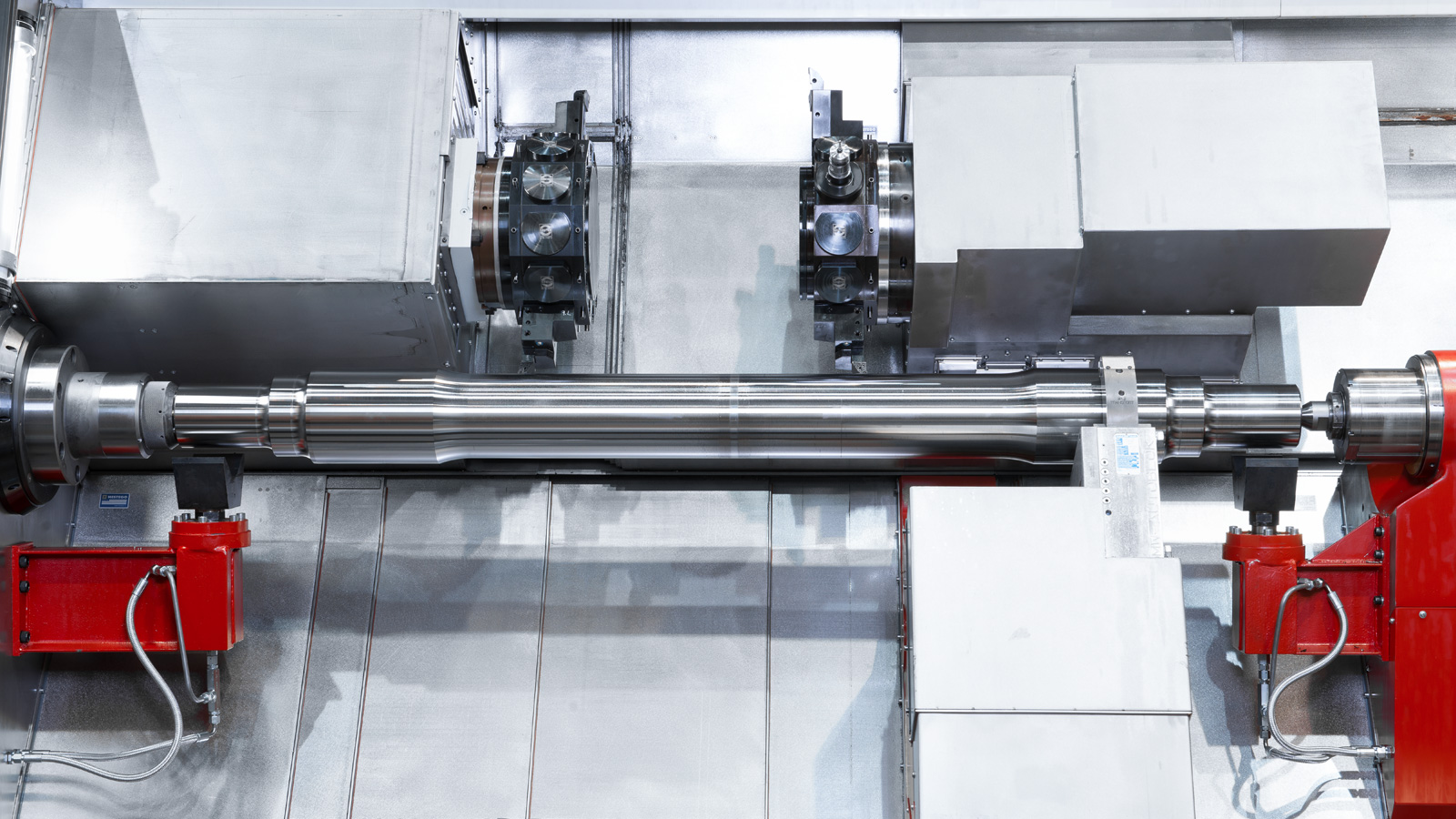

SPH 50

Max. Ø soutružení: 500 mm

Max. délka soustružení: 3 000 mm

Max. hmotnost obrobku: 2 500 kg

Max. výkon S1: 100 kW

| TECHNICKÁ DATA | SPH 50 | SPH 50 D | SPH 50 DS | |

|---|---|---|---|---|

| Řídící systém | ||||

| SIEMENS | - | SINUMERIK 840D SL | SINUMERIK 840D SL | SINUMERIK 840D SL |

| Pracovní rozsah | ||||

| Oběžný průměr nad ložem | mm | 760 (*910) | 760 | 760 |

| Max. průměr soustružení pravým/levým suportem | mm | 530 / 530 | 530 / 400 | 530 / 400 |

| Max. délka soustružení | mm | 3 000 * | 3 000 * | 2 700 * |

| Max. hmotnost obrobku | kg | 2 500 | 2 500 | 2 500 |

| Pracovní vřeteno | ||||

| Přední konec vřetena (ISO 702-1) | - | A15 | A11 | A11 |

| Vrtání vřetena | mm | ø 125 | ø 135 | ø 135 |

| Hlavní pohon | ||||

| Výkon motoru (S1) | kW | 110 | 60 | 28 |

| Kroutící moment (S1) | Nm | 4180 | 1700 | 1680 |

| Rozsah otáček vřetena | min-1 | 20 - 2 100 | 20 - 2 800 | 20 - 2 800 |

| Počet otáčkových řad | 2 | 2 | 2 | |

| Pomocné protivřeteno (elektrovřeteno) | ||||

| Přední konec vřetena (ISO 702-1) | - | - | - | A8 |

| Vrtání vřetena | mm | - | - | ø 65 |

| Výkon motoru (S1 / S6-40%) | kW | - | - | 22 / 28 |

| Kroutící moment (S1 / S6-40%) | Nm | - | - | 300 / 384 |

| Rozsah otáček vřetena | min-1 | - | - | 20 - 4000 |

| Max.kroutící moment osy C | Nm | - | - | 270 |

| NC I - horní suport pravý | ||||

| Osa X - max.zdvih | mm | 225 (ø84 - 530) | 280 (ø0 - 530) | 280 (ø0 - 530) |

| Osa Z - max.zdvih | mm | 2 385 | 2 620 | 2 600 |

| Rychoposuv X / Z | m/min | 12 000 / 15 000 | 12 000 / 15 000 | 12 000 / 15 000 |

| NC II - horní suport levý | ||||

| Osa U - max. zdvih | mm | 225 (ø88 - 530) | 200 (ø30 - 400) | 200 (ø30 - 400) |

| Osa W - max. zdvih | mm | 1 810 | 2 030 | 2 030 |

| Rychloposuv U / W | m/min | 12 000 / 15 000 | 12 000 / 15 000 | 12 000 / 15 000 |

| Nástojové hlavy NC I a NC II | ||||

| Počet poloh - levá hlava / pravá hlava | - | 8 / 8 | 12 / 12 | 12 / 12 |

| Velikost drážky pro povrchové nástroje | mm | 40 | - | - |

| Průměr upínacího čepu držáku nástrojů DIN 69880 | mm | - | 50 | 50 |

| Max. otáčky nástrojového vřetena | min-1 | - | 3000 | 3000 |

| Výkon rotačních nástrojů S1/S3-40% | kW | - | 8,8 / 20,3 | 8,8 / 20,3 |

| Kroutící moment rotačních nástrojů S1/S3-40% | Nm | - | 28 / 71 | 28 / 71 |

| Přesnost opakovaného najetí ČSN ISO 230-2 | ||||

| Osa X / U | mm | 0,006 / 0,005 | 0,006 / 0,005 | 0,006 / 0,005 |

| Osa Z / W | mm | 0,013 / 0,013 | 0,013 / 0,013 | 0,013 / 0,013 |

| Dolní saně s lunetou | ||||

| Osa Q - max. zdvih | mm | 1 715 | 1 860 | 300 |

| Příčný výsuv lunety | mm | 280 | 280 | - |

| Koník | ||||

| Průměr pinoly | mm | 190 | 190 | - |

| Zdvih pinoly | mm | 180 | 180 | - |

| Kužel dutiny MORSE | 6 | 6 | - | |

| Zdvih tělesa koníka | mm | 1 710 | 1 860 | - |

| Rozměry stroje | ||||

| D׊×V (včetně dopravníku třísek) | mm | 8 100 × 3 435 × 2 286 | 8 124 × 3 435 × 2 230 | 8 124 × 3 435 × 2 230 |

| Hmotnost stroje | kg | 27 000 | 26 000 | 26 000 |

NORMÁLNÍ PŘÍSLUŠENSTVÍ | SPH50

Nástrojové hlavy

Koník

Dálková diagnostika

Přenosný panel s ručním kolečkem

Úprava pro připojení zařízení pro monitorování řezného procesu Prometec

Úprava pro připojení zařízení Marpos (aktivní kontrola dílce)

Uzamčení dveří rozvaděčů

Osvětlení pracovního prostoru

Návod k obsluze stroje a hlavních komponentů, zápis o zkoušce přesnosti

Měření životnosti nástrojů a zatížení stroje pomocí software Prometec

Centrální mazání

Úprava vzduchu

Ethernet, flash paměť

ZVLÁŠTNÍ PŘÍSLUŠENSTVÍ | SPH50

Chladící jednotka (+ 50C ÷ + 450C)

Přizpůsobení pro manipulátor

Světelná signalizace provozu stroje

Pohon klepacího táhla

Upínání Forkardt 3 LZD 500

Dopravník třísek

Chlazení Z1 3000/S

Chlazení Z2 3000/S

Úprava řezné kapaliny BS

Nádrž řezné kapaliny 900 l

Luneta SMW SLU4 vč.přívodů,držáku,rozvodu,ovládání

Odsávání par

Rozvod vzduchu

Podpěry dílců

Odsouvání krytu 3000

Aktivní kontrola obrobku Marpos

Základový materiál

Zvedací zařízení

NORMÁLNÍ PŘÍSLUŠENSTVÍ | SPH50 D

Nástrojové hlavy s pohonem rotačních nástrojů

Koník

Dálková diagnostika

Přenosný panel s ručním kolečkem

Úprava pro připojení zařízení pro monitorování řezného procesu Prometec

Úprava pro připojení zařízení Marpos (aktivní kontrola dílce)

Uzamčení dveří rozvaděčů

Barva euro nebo bona

Osvětlení

Konverzace anglická / německá / česká

Návod k obsluze stroje a hlavních komponentů, zápis o zkoušce přesnosti

ZVLÁŠTNÍ PŘÍSLUŠENSTVÍ | SPH50 D

Chladící jednotka (+ 50C ÷ + 450C)

Přizpůsobení pro manipulátor

Světelná signalizace provozu stroje

Upínání KFD-HS 400/UVN 215

Upínací válec UVN 215

Dopravník třísek

Chlazení Z1 3000/S

Chlazení Z2 3000/S

Úprava řezné kapaliny BS

Nádrž řezné kapaliny 900 l

Luneta SMW SLU4 vč.přívodů,držáku,rozvodu,ovládání

Odsávání par

Rozvod vzduchu

Podpěry dílců

Odsouvání krytu 3000

Aktivní kontrola obrobku Marpos

Základový materiál

Zvedací zařízení

NORMÁLNÍ PŘÍSLUŠENSTVÍ | SPH50 DS

Protivřeteno

Nástrojové hlavy s pohonem rotačních nástrojů

Dálková diagnostika

Přenosný panel s ručním kolečkem

Osa C na protivřetenu

Úprava pro připojení zařízení pro monitorování řezného procesu Prometec

Uzamčení dveří rozvaděčů

Barva euro nebo bona

Osvětlení

Konverzace anglická / německá / česká

Návod k obsluze stroje a hlavních komponentů, zápis o zkoušce přesnosti

ZVLÁŠTNÍ PŘÍSLUŠENSTVÍ | SPH50 DS

Chladící jednotka (+ 50C ÷ + 450C)

Přizpůsobení pro manipulátor

Světelná signalizace provozu stroje

Dopravník třísek

Chlazení Z1 3000/S

Chlazení Z2 3000/S

Úprava řezné kapaliny BS

Nádrž řezné kapaliny 900 l

Luneta SMW SLU3.1– levá-pevná+saně

Luneta SMW SLU3.1– pravá-pevná+saně

Přizpůsob.pro hydraul.dotlačování protivřetenem

Upínací válec neprůchozí, levé vřeteno

Upínací válec dvojčinný,neprůchozí - protivřeteno

Chlazení Z1 3000/S a magnet. filtrací

Chlazení Z2 3000/S a magnet. filtrací

Odsávání par

Rozvod vzduchu

Odsouvání krytu 3000

Aktivní kontrola obrobku Marpos

Základový materiál

Zvedací zařízení

Základní koncepce

Odlitek lože ze šedé litiny je skříňové koncepce. Rovina vodících ploch je skloněna o 30°od svislé roviny. Horní vodící plochy jsou ocelové, kalené (tvrdost 600-730 Hv) a broušené. Dolní vodící plochy jsou kombinací kalených, ocelových a litinových vedení (400 HB). Lože je připevněno k litinové základně vyplněné formovací hmotou. Na základně jsou upevňovací plochy pro základnu hlavního motoru, krytování a pro nosné konstrukce uzlů stroje. Na horní ploše lože jsou vedeny el. vodiče a jednotlivá potrubí tak, aby byly dobře přístupné obsluze a údržbě. Kondenzát a mazací olej jsou sváděny zpět do násypky dopravníku třísek vrtanými kanály v loži.