ROLLER 2800

Oběžný průměr bez využití naklápění osy B: 300 mm

Max.síla válečkování bez využití naklápění osy B: 50 kN

Max. hmotnost obrobku: 1 000 kg

Výkon S1: 11 kW

| TECHNICKÁ DATA | Jednotka | Roller 2800 CNC |

|---|---|---|

| Pracovní rozsah | ||

| Geometrická a pracovní přesnost | ISO 1708 | |

| Oběžný průměr bez využití naklápění osy B | mm | 300 |

| Oběžný průměr s využitím naklápění osy B do ± 30° | mm | 280 |

| Oběžný průměr s využitím naklápění osy B do ± 35° | mm | 250 |

| Zdvih pinolí válečkovacích hlav | mm | 112 |

| Rozsah válečkovaní síly | kN | 1-50 |

| Max.síla válečkování s využitím naklápění osy B (B = ± 35°) | kN | 20 |

| Max.síla válečkování bez využití naklápění osy B (B = 0°) | kN | 50 |

| Vzdálenost hrotů | mm | 2876 |

| Max. hmotnost obrobku | kg | 1000 |

| Pracovní vřeteno | ||

| Přední konec vřetena (DIN 55027, 55029) | - | B11/C11 |

| Vrtání vřetena | mm | 106 |

| Kužel ve vřetenu - metrický | mm | 112 |

| Řídící systém | ||

| SIEMENS SINUMERIK | - | 840D |

| Hlavní pohon | ||

| Výkon motoru (S1) | kW | 11 |

| Max. kroutící moment na vřetenu (S1) | Nm | 297,5 |

| Rozsah otáček vřetena | min-1 | 0-400 |

| Osa B | ||

| Převod šnekových převodovek | - | 1:40 |

| Převod čelního ozubení mechanismu naklápění | - | 1:12 |

| Rozsah naklápění | ° | ± 35 |

| Rychloposuv | min-1 | 10 |

| Osa Z | ||

| Kuličkový šroub - průměr / stoupání | mm | 50/10 |

| Zdvih | mm | 2876 |

| Rychloposuv | m/min | 10 |

| Max. posuvná síla | kN | 20 |

| Přesnost opakovaného nastavení polohy | mm | 0,015 |

| Koník | ||

| Průměr pinoly | mm | 115 |

| Zdvih pinoly | mm | 160 |

| Kužel dutiny v pinole | MORSE | 6 |

| Hydraulický agregát | ||

| Objem hydraulického oleje | l | 10 |

| Pracovní tlak čerpadla | bar | 110 |

| Jmenovitý průtok čerpadla | l/min | 11 |

| Jmenovitý výkon motoru | kW | 3 |

| Mazání válečkovacích nástrojů | ||

| Jmenovitý tlak čerpadla | bar | 3 |

| Jmenovitý průtok čerpadla | l/min | 0,9 |

| Objem nádrže | l | 32 |

| Jmenovitý výkon motoru čerpadla | kW | 0,05 |

| Rozměry stroje | ||

| Délka × šířka × výška | mm | 4000x1815x1863 |

| Hmotnost stroje | kg | 6200 |

| Maximální celkový příkon stroje | ||

| Příkon | kVA | 30 |

STANDARDNÍ PŘÍSLUŠENSTVÍ

Osvětlení pracovního prostoru

Otočný hrot Röhm 116 Mk6 (604H)

Kalibrační siloměr

Redukční vložka do vřetena Metric 112/Mk 6

Základní těleso unašeče

Mazání válečkovacích kladek

Vana na mazací olej pro válečkování

Automatické centrální mazání

Nářadí k obsluze

Průvodní dokumentace

Řídící systém SIEMENS 840 D

ZVLÁŠTNÍ PŘÍSLUŠENSTVÍ

Válcovací držák (sada 2ks)

Válcovací kladky (sada 2ks)

Dálková diagnostika

Kotevní materiál

Speciální otočný hrot

Signalizace stavu stroje - maják

Zvedací zařízení

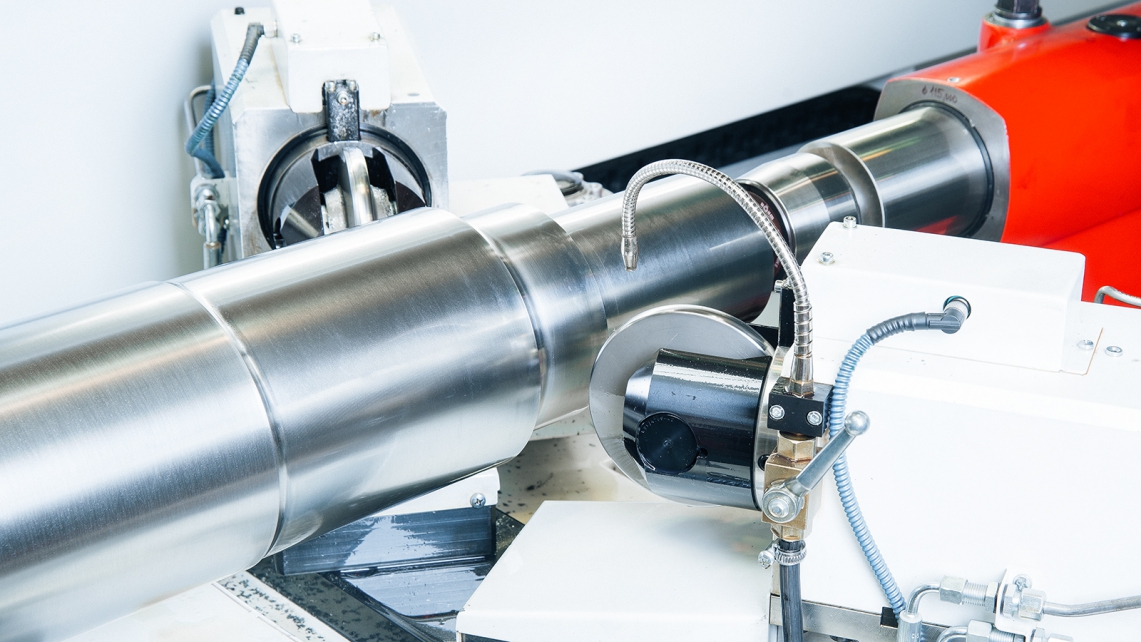

Základní koncepce

- Technologie tváření za studena – zpevňování materiálu

- Speciální stroj, je skeletem stroje odvozen ze standardního soustružnického stroje MASTURN 70/3000 CNC.

- Funkce stroje spočívá v technologii válečkování válcových, kuželových a přechodových rádiusových ploch hřídelových součástí např. náprav vozidel.

- Použití stroje pro specializovanou výrobu součástí s využitím technologie válečkování povrchu.

- Zařízení pro válečkování je umístěno na podélném suportu.

- Suport se pohybuje pomocí CNC řízené osy Z po loži stroje v podélném směru.

- Pohyb v ose X je realizován pinolemi válečkovacích hlav, do kterých se upínají vlastní válečkovací nástroje.

- Pohyb pinolí a síla válečkování je vyvozena hydraulicky.

- Standardně je stroj vybaven hydraulickým agregátem.

- Plynulé změny tlaku a síly na válcovací nástroje během pracovního cyklu v definovaném rozsahu tlaků.

- Zobrazení aktuální válečkovací síly, zaznamenávání a archivace.

- Koník s hydraulicky ovládanou pinolí je vybaven zvláštním mechanickým aretačním zařízením pro bezpečný přenos osových sil

- Vřeteník stroje je uložen na loži na zesíleném středícím čepu.

- Samostatné olejové hospodářství včetně nádrže a vany pod pracovním prostorem stroje.

- Celý systém válečkovacího suportu je integrován do zakrytovaného prostoru stroje.

- Kluzné vodící plochy přídavného válečkovacího suportu jsou napojeny na centrální mazací systém stroje.

- Stroj je možno provozovat v ručním i automatickém cyklu.

Výhody válečkovaného povrchu spočívají v dosažení hladkého povrchu součásti tvářením povrchové vrstvy za studena. Kvalitou opracování nahrazuje technologii broušení, ovšem bez přesností rozměru opracované plochy jako při broušení. Válečkování je vhodné jako dokončovací operace pro zpevnění povrchů netolerovaných rozměrů nebo jako technologie zpevnění povrchové vrstvy před dokončovacím broušením ploch na tolerovaný rozměr.

Válečkování se využívá především z důvodů úspory materiálu až o 8%, dále vyšší odolností proti vzniku únavového lomu tj. vyšší únavovou pevností v cyklickém namáhání součásti, zvýšená tvrdost a velmi hladký povrh, zajišťuje vyšší odolnost proti otěru a vzniku koroze, další nemalou výhodou pro životní prostředí je možnost nahradit molybdenový nástřik oválečkováním povrchu.

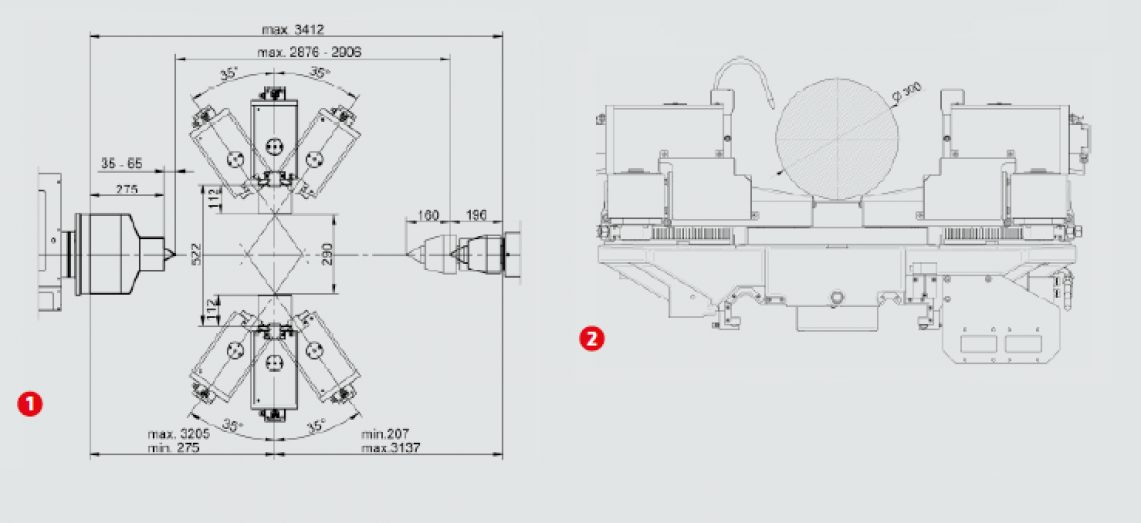

Pracovní prostor

- Pracovní prostor stroje, kde jsou v první řadě naznačeny vzdálenosti a rozměry, co se týká upnutí hřídele, tzn. upínač vřetene, vzdálenost čela upínače od čelní plochy vřetena 275mm, rozjezd koníka stroje (vztaženo na vzdálenost zasunuté pinoly koníka od čela vřetena stroje tj. 3412mm, velikost výsuvu pinoly 160mm a vzdálenost špičky otočného hrotu (v našem případě hrot Röhm MK6 VEL.116 – Id.Nr.093439) od čela pinole koníku 192mm. Celková vzdálenost mezi hroty je potom 2876-2906mm v závislosti na tvaru a velikosti středícího důlku nápravy. Dále je v pracovním prostoru naznačen rozjezd suportu s válečkovacími rolnami se vzdálenostmi právě k čelu vřetena a čelu zasunuté pinoly koníka, dále je naznačen úhlový výkyv válečkovacích pinolí (±35 stupňů), pozice středu kolem kterého naklápění probíhá tj. 290mm a hodnota vzdálenosti čel zasunutých pinolí válečkovacích hlav 522mm a výsuv každé z pinolí 112mm. Většina rozměrů je stanovena k čelu vřetena, čelu pinole koníka a k čelům pinolí válečkovacích hlav, protože samotný upínač do vřetene, hrot do koníka a válečkovací nástroje se volí a konstruují speciálně dle požadavku zákazníka a jejich hodnoty se mohou lišit.

- Maximální oběžný průměr součásti bez naklonění válečkovacích hlav